If you are a wine producer, you know exactly what we are talking about. The problem of TCA and chloroanisoles spoiling the taste of our wine is a relatively new one. It suddenly became one of the biggest headaches for any sparkling wine producer.

Although the issue only affects about 4% of wine bottled worldwide, it has created a resounding problem that, given the difficulty in detecting and eradicating it, has caused a certain degree of anxiety among producers.

Stick around and we’ll explain where it comes from and how to solve it.

What is TCA?

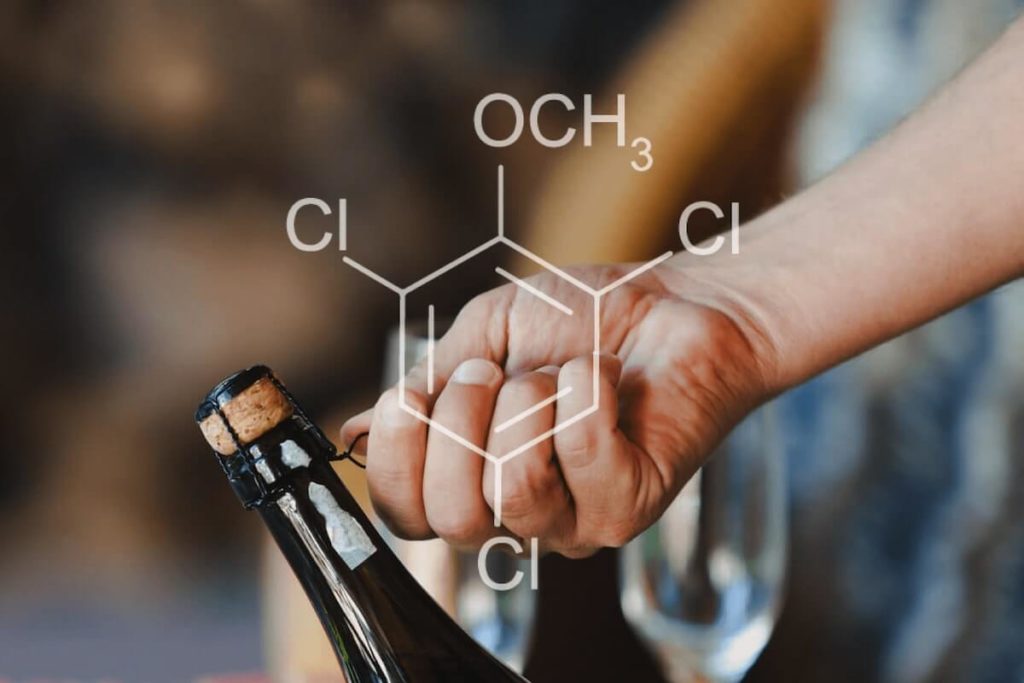

Trichloroanisole, better known by its initials TCA, is an anisole-derived molecule that, after coming into contact with sparkling wines, triggers a contamination that can result in a bad taste and smell in the product.

While totally harmless to humans and even safe to consume, this contamination can severely affect the organoleptic characteristics of the wine, completely tainting the taste and smell desired by the producers and consumers concerned, who are often forced to discard the bottle completely.

The problem of anisole contamination of sparkling wine is not only limited to the notorious and much detested TCA; there is a large “family” of molecules that cause this annoying contamination:

- 2, 3, 4, 6-Tetrachloroanisole (Teca)

- 2, 4, 6-Tribromoanisole (TBA)

- 2, 4, 6-Trichloroanisole (TCA)

- Pentachloroanisole (PCA)

As their names reveal, they all contain a molecule called anisole, which is the result of the biomethylation developed by certain fungi and which we will explain later.

What causes TCA?

Traditionally understood as a fungus or bacterial contamination of cork stoppers, the anisole that causes this problem ironically originates from the agents precisely designed to remove this contamination.

The cause of this problem is simple: chlorine.

Simple yet tremendously complex. We will try to synthesize the process that causes the appearance of this substance:

1 – The source of the problem are the so-called chlorophenols. These particles have a structure formed in part by chlorine (Cl) and are present in many substances and places: disinfectants, detergents, preservatives, pesticides and even in the air.

2 – When the corrosive effect of chlorophenols comes into contact with certain fungi, these fungi defend themselves by initiating a process called biomethylation, by which they transform the harmful chlorophenol molecules into other molecules that are harmless to them, called anisoles.

3 – After the anisoles are generated, they can manifest as any of the substances we have previously mentioned, adhering to a surface or even floating in the air.

4 – If they come into contact with sparkling wine, they contaminate the product, resulting in a wide range of issues. The most serious and well-known of these is the undesired alteration to the taste and smell of the wine, although it should be noted that this occurs to varying degrees and is often imperceptible to the vast majority of consumers.

In any case, anisole contamination is a problem to be absolutely avoided by any producer who values their product and wants to offer the highest quality in every bottle.

Cork taint?

This is undoubtedly the biggest myth about TCA. We have already talked about how this contaminant is produced and the process that causes it, but what transmits it, and how does it finally reach our sparkling wines?

The answer is wide ranging. Anisoles are transmitted in many different ways and it is through them that they come into contact with wine.

The most common forms of transmission are through:

- the stopper

- the wooden barrel or steel tanks

- the bottle

- tools used in production

- the air in the cellar

Anisole is produced wherever the fungus comes into contact with chlorophenols and, from there, it will pass into our wine.

This is why it is misleading to attribute the source of contamination exclusively to the bottle stopper, and we must clarify that the cause is the presence of chlorine and fungi near any ingredient that is involved in the winemaking process.

It was precisely this myth of the “TCA problem” that forced the cork industry to develop specific technology and strict controls and analyses for this issue. The result is that today, of all the materials involved in the process of creating sparkling wine, cork is a very safe element despite its bad reputation. Even though cork stoppers are commonly blamed for contamination, in reality it could have been caused by any of the other elements.

This is why sanitization and the proper preservation of materials must be a priority and an absolute constant for the eradication of this problem.

How is TCA detected?

This is one of the major challenges during the production process.

Unfortunately, detecting possible sources of contamination before or during bottling involves cumbersome processes that greatly delay production, but above all they involve numerous analyses that are associated with very high costs that reduce the profits that we would obtain with the final production.

On the other hand, identifying contaminations after the fact, although much simpler, is often of little or no effect. There are currently highly specialized professionals in the identification of odors and flavors that denote this contamination, but the processes are complex (and costly) since each bottle must be analyzed after the first uncorking.

It goes without saying that these measures are usually taken only in very specific situations and the efforts of most producers are focused almost exclusively on prevention. Here is how to prevent such contamination in your winery.

In the case of stopper manufacturers, TCA is identified in the reception of raw materials and in the exhaustive controls of the production process.

How to avoid TCA contamination

Here comes the good news: avoiding the TCA problem and anisoles is possible.

By incorporating certain work procedures and some technological elements in our winery, we will be able to achieve safety guarantees close to 100% and so finally rest easy and focus on what we like the most—making quality sparkling wine.

Some such actions include:

- Completely phasing out the use of products containing chlorine in their formulation

- Sanitization of the facilities and tools involved in the production process

- Using ozone treatments in the disinfection of facilities.

- Requesting the necessary safety certifications from suppliers

- Reducing excessive humidity in the winery

- Using industrial air filters that guarantee the removal of contaminating particles

- Following the manufacturer’s recommendations for the preservation of the stoppers

In the manufacture of stoppers, contamination is avoided by carefully selecting the raw materials entering production. Performing TCA controls in the stages of the production process and not using chlorinated products in the cleaning of the facilities.

Conclusions

Although the problem of TCA and anisoles affects a very small number of bottles, it is a problem of great concern to producers.

To ensure that our bottles are free of these contaminants, we need only implement prevention systems in our facilities that ensure the absence of chlorine, the hygiene of the elements used and the air in our spaces.

We must also broaden our spectrum in terms of possible sources of contamination if we really want to get rid of this problem and stop assigning the blame exclusively to stoppers.

A TESA tenim un dels estàndards més alts en la indústria amb el nostre mètode únic de mesurament del TCA i altres possibles agents contaminants, garantint nivells imperceptibles i oferint una altíssima traçabilitat al llarg de tota la nostra producció i els nostres lots de producte.

Si vols més informació pots posar-te en contacte amb nosaltres i estarem encantats d’ajudar-te.